Table of Contents

Coffee Cup with Face Tutorial

If you have access to a 3D scanner, all sorts of truly personalize objects are possible!

In this tutorial, we take a coffee cup found on SketchUp Warehouse and combine it with the scan of a real Viking face. With access to repositories like SketchUp, Forme It, 3D Burrito, etc. and a 3D scanner such as Fuel3D, anyone can put together unique designs – no modeling skills required!

This tutorial will also demonstrate how Envelope can transform a common problem with some models - that it has no thickness and can not be printed, and in this case can even fix a gap between the handle and the cup.

TIP: Remember to pay attention to the bottom right hand corner - this is where the progress bar for each operation will be displayed.

Step 1: Open Cup

Open the cup: File > Open Stock Model > Cup.

MeshUP will automatically detect issues with an imported object and display them with different colors. The Properties dialogue box will list the types of issues.

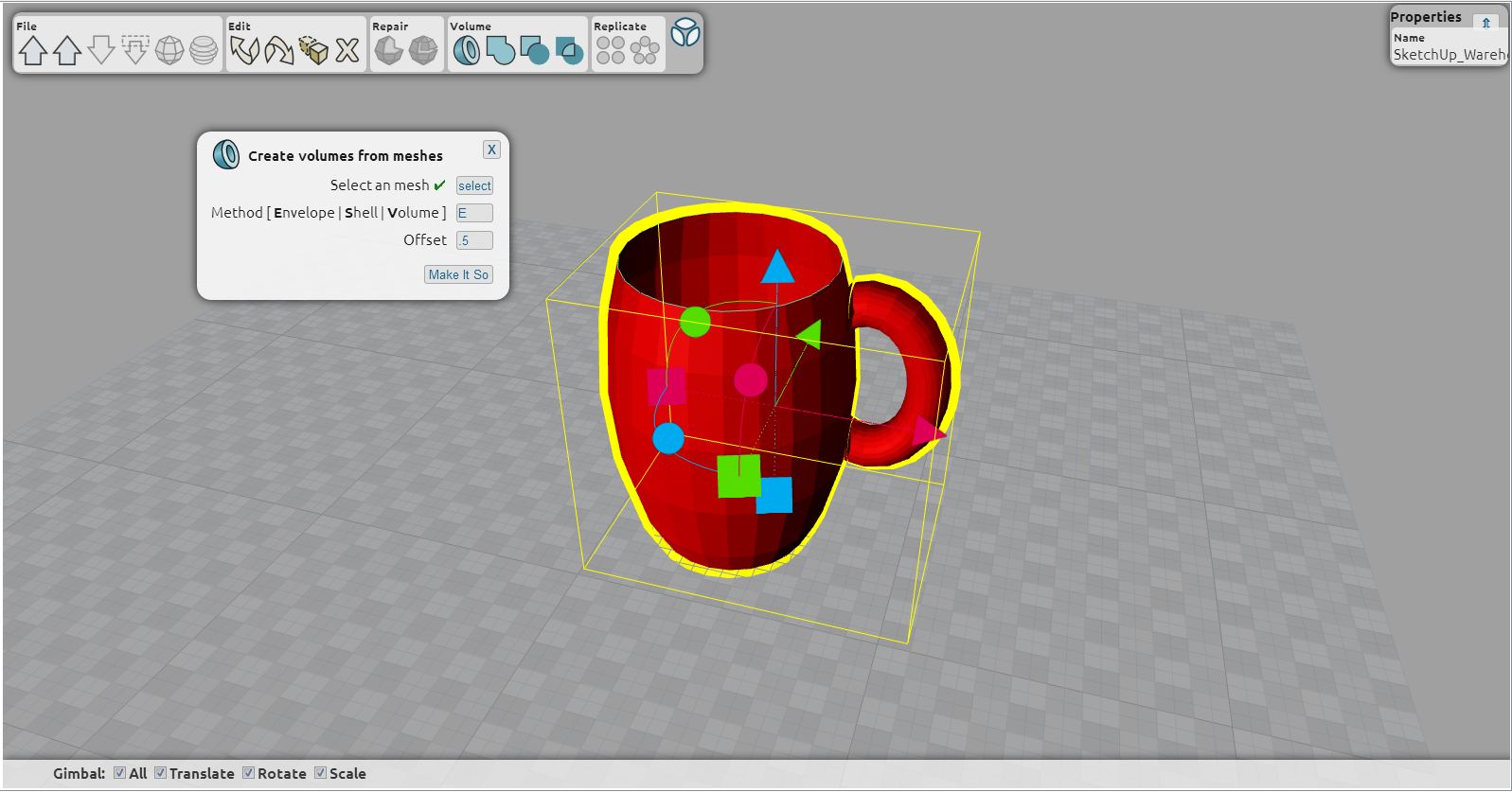

Notice that the cup is red, which means it has surface issues. Also notice that there is a gap between the handle and the cup.

Step 2: Convert to Volume

Before working with any imported objects in MeshUP, you must convert them to one type of Volume:

- Envelope: this will work with any mesh, even polygon soup! Envelope can be thought of as inflating the object with air. The higher the offset, the more fine detail you will lose.

- Shell: requires the mesh has no intersections, degenerates, flipped faces, cracks but it can have holes. Shelling produces a one sided offset and can be thought of as a single sided envelope. Shelling preserves the positive normal surface, so on one side you get the exact surface, on the side the offset is applied.

- Volume: requires the mesh to be completely manifold: no intersections, degenerates, flipped faces, cracks or holes.

For objects like the cup, Envelope is ideal as it adds thickness and in the process closes gaps like the one between the top of the handle and the cup.

Select the cup, click on the Volume icon from the menu and type E for Envelope and type 1 for the Offset value. The cup will turn from grey to tan, which means it is now considered a Volume. Notice that there is no longer a gap between the handle and the cup.

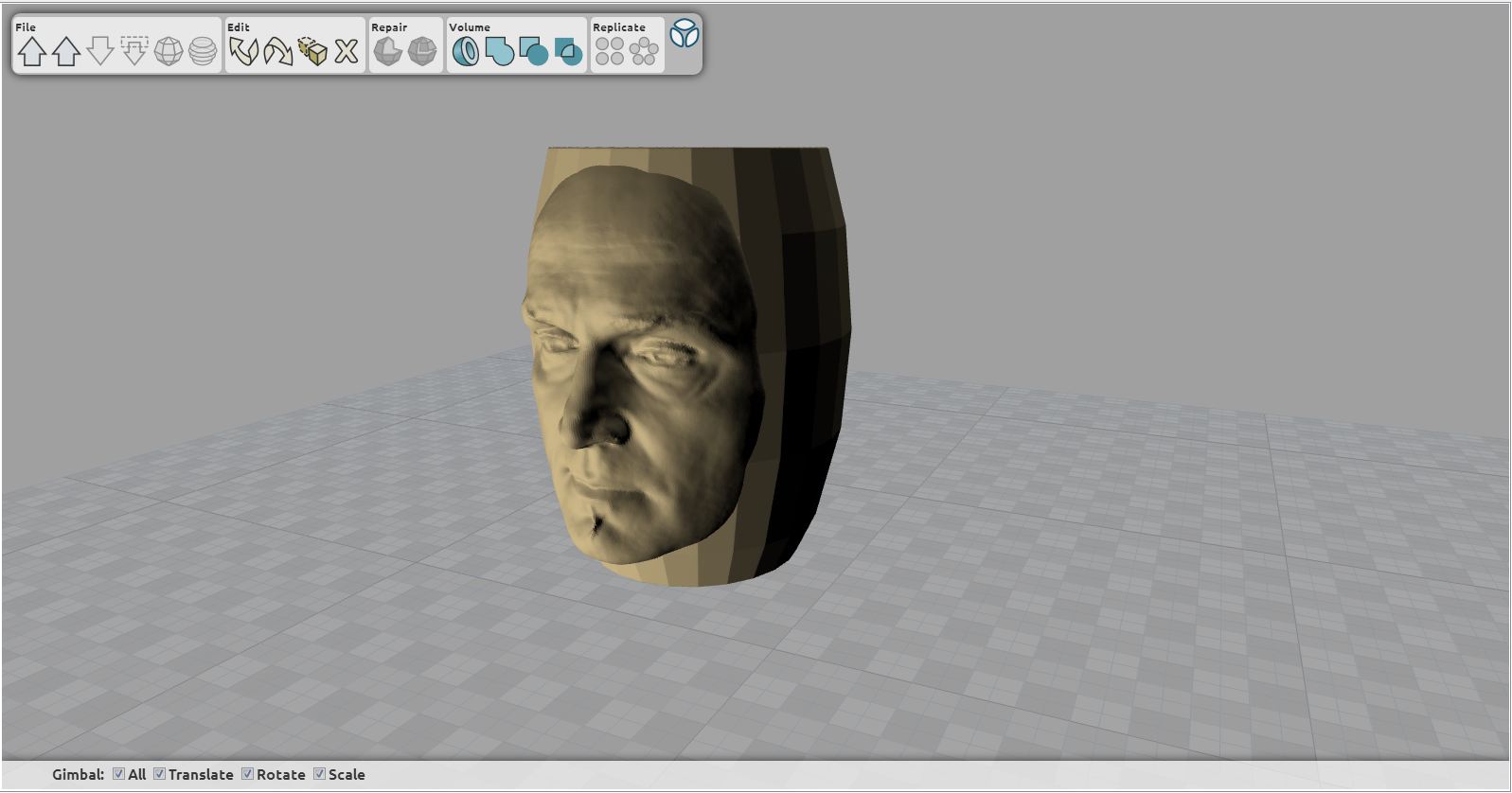

Step 3: Open Face & Convert to Volume

Open the Viking face: File > Open Stock Model > Viking. Notice that the face is grey, meaning it has no errors.

Select the face, click on the Volume icon from the menu and type V for Volume. The face will turn from grey to tan, which means it is now considered a Volume.

Step 4: Move & Subtract

Move the face so it is positioned as though it is pushing through the cup, as shown below. Do not worry about the part showing through on the inside of the cup. We will remove this excess bit next.

Open the filled cup: File > Open Stock Model > Cup Filled. We will use this to subtract the part of the face that is sticking through the inside of the cup. If you have not moved the original cup, the filled in cup will import directly inside of the original cup.

Select the filled in cup, click on the Volume icon from the menu and type V for Volume. The cup will turn from grey to tan, which means it is now considered a Volume.

Select the face, then click on the Subtract button. Select the base object will have a green check box next to it.

Next to Select objects to subtract, click once on the Select button. The Select box will turn blue. Click once on the filled in cup and a check mark will now appear next to this second Select box. Click Make It So.

The inside of the face is no longer pushing through the inside of the cup.

Step 5: Union

Select the face, then click on the Union button. Select the base object will have a green check box next to it.

Next to Select objects to union with, click once on the select button. The select box will turn blue. Click once on the cup and a check mark will now appear next to this second select box. Click Make It So.

(Note that Blend is not yet available in the current version of the Preview.)

Watch the progress bar on the lower right hand corner to know when the operation is complete.

Merry Modeling!